| 2024 | Quarter 3 | Issue Thirteen |

the voyager Newsletter

Welcome to Dupre Marine’s Quarterly Newsletter!

IN THIS ISSUE

Employee Spotlights

#Deckhandlife

Recipes for the Whole Crew

Just for Fun Quiz for Everyone

Calvin’s Corner

Safety Topic

Crew Safety Quiz

DMT Anniversaries for this Quarter

Company News & Updates

dmt’s Wheelhouse spotlight:

There is no denying the M/V JERRY PORCHE looks impeccable and that starts from the top with Captain Jade O’Neal!

Jade, the skilled and spirited Captain of the M/V JERRY PORCHE, renowned for his leadership and dedication, represents excellence in safety, a tight-knit crew family that works perfectly as a team and approaches each day with a goal to be the best. He consistently praises his crew, creating an awesome team that has fun, works hard and provides a positive work atmosphere. Captain Jade can clown around with the best of them in that crew! Under his leadership, the Jerry mirrors his commitment by consistently looking amazing and he and his crew work efficiently, showing his commitment to excellence. He created a unmistakable crew culture and safety culture on his boat.

Jade is also a dedicated family man here in Houma, LA. He looks forward to those days off to spend quality time with his family especially his two daughters, making sure he gets to see their special activities like plays and functions. All of his hard work is for his family!

And Jade has a strong focus on and off the boat for health, eating well and working out and encouraging others to do the same. In this industry that is a difficult thing to do, but with his strong work ethic, there is no doubt he will succeed at this as well.

Captain Jade’s effective leadership and teamwork has significantly contributed not only to the success of the M/V JERRY PORCHE, but for Dupre Marine for the past 5 years and we look forward to his long career at the helm.

DMT SPOTLIGHT:

In just over a year at Dupre Marine, Kyle Thibodaux is the LEAD man on the M/V AMBRIE DUPRE on deck. His success in the past year comes from a strong focus on safety, hard work, and commitment to Dupre Marine's values of #PRIDEINYOURRIDE. This dedication shows in the careful maintenance and appearance of the Ambrie, demonstrating leadership amongst the crew. He cares about his work and it shows! And Kyle is not just a hard worker, but a great guy who is easy to work with and always strives to be the best.

Outside of work, Kyle is married with two sons and they just found out they expecting a daughter in April! The family lives in Hammond, Louisiana where they make lasting memories. During his off-time, Kyle enjoys not only family fun, but also outdoor hobbies like duck hunting and fishing. And since family is important to Kyle, when he is back on the boat, he gets to work with his brother, Relief Captain Matt Gisclair and the brother bond is strong.

Kyle is ready to advance his career and the next stop is the Wheelhouse, following in Matt’s footsteps. Entering the Steersman program in early 2025, we look forward to the next couple of years of his hard work paying off. It is exciting to watch careers grow at Dupre Marine and Kyle with no doubt will do great work with his focus and determination to make it happen!

#DECKHANDLIFE

This new section will be dedicated to the deckhands and photo features from the Quarter with a quick deckhand topic. These crew members are starting their careers on deck and we all know to have a great career as a Wheelman or Tankerman, you have to be a damn good deckhand!

A criss-cross fashion of putting on a lashing allows as much of the slack as possible manually to be removed from the line. Lashings are usually put over the top of the wires at a tightened coupling as a safety precaution. The heavy or excessive strain from steering at times can result in a “parting” of a wired or chain. This can cause the tow to break-up. Using a “safety lashing” over the hard rigging will help keep the tow intact and save a lot of extra work and time.

Pic cred goes to Jason McCranie

RECIPES for the Whole Crew AND BOAT!

It’s football season and that requires snacks for the times you watch the games! For this recipe Michael used a smoker, but this will work in the oven or air fryer too.

And for dinner, make the perfect comfort food from Mike Serdinsky: Cheesy Shepherd’s Pie. Guaranteed a happy full crew!

SNACK MIX FOR FOOTBALL AND MOVIE NIGHTS

Recipe from Michael Ortego

Unsalted Butter-1 stick

Worcestershire Sauce-3 teaspoons

Garlic Powder-2 teaspoons

Onion Powder-2 teaspoons

Meat Church the Gospel Seasoning-3 tablespoons (Walmart or Academy)

Cheez-its-12oz

Rice Chex cereal-12oz

Mini pretzel twists or checks-12oz

Salted Peanuts-12oz

1. Make the seasoning mixture. Place butter in a medium, microwave-safe bowl. Microwave in 10-second intervals, stirring between each, until melted, 50 to 60 seconds total. (Alternatively, melt in a small saucepan on the stovetop over low heat.) Add Worcestershire sauce, Meat Church seasoning, garlic powder, onion powder. Whisk well to combine.

2. Combine the Snacks

3. Toss with butter. Pour half of the butter mixture over the snack mixture and gently toss to coat. Pour in the remaining butter mixture and gently toss again so all the pieces are evenly coated.

4. Set the smoker to 250 and cooked for a hour and a half. (Alternatively this can also be baked in the oven for a non-smoked flavor)

cheesy shepherd’s pie

Recipe from Mike Serdinsky

Brown 4 pounds of lean ground beef in a Dutch oven with salt, pepper, rosemary, thyme, parsley and a few shots of Worcestershire sauce.

Drain 2 bags of thawed mixed frozen vegetables and add to the meat. Add one pack of mushroom gravy.

Boil 10 large red potatoes and mash with butter and cream cheese.

Spread the meat and vegetable mixture in the bottom of the casserole dish. Spread the mashed potatoes over the top of the meat/vegetables. Top with a half of a large brick of Velveeta cheese.

Bake in the oven at 375 for approximately 45 minutes to an hour

sweater weather simmer pot

From the home of Patrick and Michelle Gunter

A recipe for your home or the boat to make it smell great for the Autumn and Winter months. Patrick and Michelle use a pot of water on top of their kerosene heater at home and add the ingredients. Also can be used stovetop on simmer.

sweater weather simmer pot:

2 Sliced Oranges

Sliced Lemon

Cinnamon Sticks

Small Pine Branches (or cedar)

Fresh Cranberries

Put ingredients in pot, add water and simmer!

fall fun quiz

See how many of these fun facts about Fall and Halloween you can figure out. Fix your Pumpkin Spiced Latte and answer these 13 questions that might get your gourd!

(As always No Googling!)

CAlvin’s Corner: The anchor

By Calvin Self

The ANCHOR dates back thousands of years. They have long been used on vessels of all types from sailboats to ships, but seldom if ever are anchors utilized in our corner of the maritime industry. Therefore, the use and meaning of the anchor in Dupre Marine Transportations logo can be a little confusing.

Anchors are one of the most widely used and oldest symbols in the world. Along with being used as a maritime symbol, the anchor has been used as a religious symbol and by empires to represent their strength and resolve. Religiously the anchor was used by early Christians as a symbol of hope and inscriptions of its use date back to the 1st century BC. Additionally, the anchor represents a strong bond, invincibility, stability, steadfastness, commitment, calm, composure, and good luck.

When the anchor is thought of as a symbol, it becomes apparent as to why it is used in the DMT logo. As a company we strive to be steadfast in our pursuit of ZERO harm. Our commitment to safe operations, our customers, and one another is one of the things that makes this company great. Furthermore, when the seas are rough, and risks are elevated mariners are legendary for remaining calm and composed. But mostly, it’s hope. The hope that our employees go home safe.

As a company we are proud. We are proud of the goals we have achieved. We are proud of the way we go about our jobs. We are proud of the commitment our employees display on a daily basis. We are proud of the company we work for. We are proud of our anchor! The next time you put on your DMT shirt, take a look at that anchor and know that it is more than a logo, it represents hope.

safety topic: Spill Prevention

You’ve seen Dupre Marine’s Policies all over the boat and in procedures (and even on this website!) and our focus right now is a commitment to safety when tanking barges and fueling boats. Part of the “ZERO” goal is spill prevention. This protects not only the environment (water, air, surrounding land and wildlife), but also the lives on your boat, barge and dock.

A spill to the water is one of the most serious incidents in this industry.

DUPRE MARINE’S ENVIRONMENT POLICY COMMITMENTS TO SAFETY:

Making the protection of the environment a priority in all activities

Taking a pro-active approach to the identification and control of environmental risks.

Reaching and maintaining our goal of ZERO spills and releases

Reducing overall emissions and waste generation

Establishing and adhering to emergency procedures and plans to identify and mitigate environmental risks

Creating and carrying out emergency drills and exercises that will ensure responses to environmental emergencies are effective

Continuously learning from our performance so we can effectively improve our processes to achieve our environmental goals

A spill or threat of a spill includes, but is not limited to, various activities such as spilling, leaking, pumping, pouring, emitting into either the surface of the water or the atmosphere, emptying, or dumping. Any oil that becomes “free” in the environment MUST be cleaned up promptly, even in cases where it has not yet been “discharged” into the water body. In other words, a leak originating from a tank or a pump must be thoroughly cleaned up, regardless of whether it actually enters the water or not. It is essential to address these situations to prevent any potential environmental harm.

The product in our barge cargo and the fuel and lube in our boats must be prevented from spilling at all costs! And if there is a spill, it is widely recognized as one of the most costly and damaging incidents that can occur in this industry. Each person has a duty and responsibility to protect our waterways and save the marine environment.

WHAT IS YOUR RESPONSIBILITY?

All crew members must help prevent oil spills and watch for events that could cause one. If a spill happens, they should quickly and safely secure the source, report it, and respond to reduce its impact. Any spill that poses a safety risk to the crew will be managed by an Oil Spill Response Organization.

Vessel PICs will closely monitor and oversee all transfers that take place on the vessel, ensuring vigilance for any spills, leaks, or potential spills that may occur during the process.

When fueling the vessel, it is essential to ensure that a quick action spill kit is always situated in close proximity to the fueling ports. This precaution helps to effectively manage any potential spills that may occur during the fueling process.

PICS will perform all necessary transfers following company policies and customer guidelines. They will carefully check tank levels using appropriate methods to ensure accuracy and safety.

Containment surrounding the fill ports must remain thoroughly dry, completely free of any debris or obstructions, and it is essential that the scupper plugs are securely in place prior to commencing the transfer process.

Alvin Miller, Tankerman Training on the M/V EVERARD DUPRE (pic cred Cris Simmonds)

Oil disposal

Harm to the environment is not only for barge product transfers or fueling a vessel, it is also a danger for disposal of oil and oily product in day to day maintenance of the vessel. It is prohibited for the discharge of oil or oily waste into the waterways. Such an incident will cause a film or sheen on the surface and can cause a sludge or emulsion beneath the surface of the water.

Use tools such as marine sanitation devices, waste oil containment equipment, compactors for solid waste and heavy duty disposal bags for garbage, oily rags and oil filters that require storage until they can be disposed of safely.

No Oil should ever be drained into the bilges. Waste Oil must be pumped into Slop Oil containers on board for disposal at designated locations.

Never use the slop oil containers for disposal of products such as paint thinners, degreasers or other hazardous waste.

Never pump bilge overboard.

Be sure that all oily waste container is triple bagged for disposal at designated locations. Make sure bag is not leaking before attempting to remove from vessel.

Always log disposal of all waste in master boat log in Helm (Waste Managment)

✅⚠️✅⚠️✅

Although the procedures are lengthy for Cargo Operations, Fueling and Lube transfers and each procedure should be reviewed by all crew members (per vessel as each can be different) and JSA’s MUST be performed for each, here are some points for each that must be followed to PREVENT SPILLS (these checklists listed below include, but are not limited to the following).

Remember all crew members must help prevent oil spills and watch for events that could cause one.

CARGO TRANSFERS:

Cargo orders should be read and understood by all crew members involved

If the barge is equipped with powered High-Level / Overfill Alarm system, system must be energized, tested and used throughout all cargo transfer operations.

Inspection checklists must be completed for: Cargo Hoses, Cargo Pumps, Gauges, Valves and ESD System, barge header and hose connections

Dock PIC must be present during all (dis)connect operations, otherwise initiate SWR

Shut down transfer if a barge alarm sounds or there is any condition that puts personnel or cargo at risk

Flange wraps must be used on all header connections including outboard header valve.

Tankerman PIC shall be on the barge at all times during cargo when the barge is in the care, custody and control of the vessel.

Complete vessel safety rounds at least every 10 minutes to properly monitor the cargo transfer including: Cargo Systems, Connections. Machinery Spaces, Vessel Moorings, Access Points.

Ensure watch change does not occur during any critical task.

DOI shall not be signed until all items and systems are verified OK, including hose connections and/or pressure test. Perform complete barge inspection to verify valve position by placing hand on every valve, tank levels, draft, Hose connection, mooring.

Notify the Officer on Watch if there is a potential for a spill and initiate an SWR if needed!

FUELING:

It takes no less than two crewmembers to fuel a vessel. Crewmembers must not engage in other activities while fueling.

Gauge each tank and determine the amount of each fuel needed.

Test high level fuel alarm. If the alarm is not functioning as intended, STOP!

Discuss amount of fuel with the vendor, flow rate and emergency stop instructions.

Nozzles with “stay(hold)-open” clips are not permitted

Inspect the fuel transfer hose for cracks, holes, soft spots, etc.

Connect fuel transfer hose and ensure proper connection

Ensure all fuel valves are aligned and ready to receive fuel.

Ensure drain plugs are in and spill containment is assessable.

Place Quick Action Spill Kit by the fill.

Deploy absorbent spill boom to prevent harm to the environment in the event there is a discharge of oil to the deck.

The PIC must maintain watch at the fill port on the main deck and another qualified crewmember will maintain visual contact between the PIC and vendor.

The tanks involved should be monitored and gauged to ensure they are not overfilled. Tanks not involved should be periodically checked.

Fill tanks to pre-determined level.

Reduce the rate prior to topping off. Do not load more than 12” from the top of the tank.

Stop the transfer and ensure that all residual fuel is removed from the hose prior to removing it from the tank.

Make sure the cap is replaced on the fuel hose when transferring the hose between tanks.

LUBE TRANSFERS:

It takes no less than two crewmembers to transfer oil to a vessel

Gauge each tank and determine the amount of each oil needed.

Discuss type of oil, amount, flow rate and emergency stop instructions with the vendor.

Inspect the transfer hose for cracks, holes, soft spots, etc.

Connect transfer hose and ensure proper connection.

Ensure valves are aligned and ready to receive oil.

Ensure drain plugs are in and spill containment is assessable.

Place Quick Action Spill Kit by the fill.

Deploy absorbent spill boom to prevent harm to the environment in the event there is a discharge of oil to the deck.

The PIC must maintain watch at the fill port on the main deck and the other qualified crewmember must have visual contact between the PIC and vendor.

Prior to transfer at full rate, start transfer at a slow rate, checking hose, connections, and transfer piping for leaks.

The tanks involved should be monitored and gauged to ensure they are not overfilled. Tanks not involved should be periodically checked.

Fill tanks to pre-determined level.

Reduce the rate prior to topping off. Do not load more than 9” from the top of the tank.

Stop the transfer and ensure that all residual oil is removed from the hose prior to removing it from the tank.

Ensure the cap is replaced on the hose when transferring the hose between tanks.

FOR THE CARGO SPILL RESPONSE AND FUEL SPILL RESPONSE, REVIEW THE EMERGENCY RESPONSE PROCEDURES (ERP 2.1) WITH YOUR CREW

⚠️Stop source of discharge

⚠️Initiate the Spill Reporting and Response Contingency Plan in the ERP.

⚠️Notify Dupre Marine Transportation Qualified Individuals (Calvin or Jaimen)

SAFETY QUIZ:

THIS IS A REQUIREMENT FOR ALL VESSEL EMPLOYEES WORKING DURING THE THIRD QUARTER OF 2024

ALL crew members must answer these questions. This quiz refers to the main safety topic for this Quarter: Spill Prevention When you are complete and hit “Submit Answers” you will get a response with your the answers and learning information. This will be a part of your safety compliance.

⚠️

It is the goal of Dupre Marine that all employees work safe hitches and go home to their families after their hitch is completed

Pic cred goes to Trent Stoute

Rory’s Favorite Quote to our Dupre Marine Team:

“Gentlemen, we will chase perfection, and we will chase it relentlessly, knowing all the while we can never attain it. But along the way, we shall catch excellence.”

~Vince Lombardi

DUPRE MARINE’S ANNIVERSARIES for 2024 third Quarter

AS OF JULY 2024:

Derrick “Bama” Jarman: 3 Years

Jade O’Neal: 5 Years

Mike Serdinsky: 3 Years

Calvin Self: 11 Years

Sidney Verdin: 10 Years

Hayden Mirambell: 1 Year

Karly Boudreaux: 2 Years

Joe Grizzard: 3 Years

Kyle Thibodaux: 1 Year

AS OF AUGUST 2024:

Michael Ortego: 9 Years

Chad Verdin: 10 Years

Jeff Verdin: 10 Years

Frank Bumgarden: 5 Years

Larry Foussell: 8 Years

Tyler Constant: 3 Years

Jeremy Scholz: 5 Years

Kory Guidry: 1 Year

Kenny Jennings: 2 Years

AS OF SEPTEMBER 2024:

Alva Dupre: 21 Years

James “Tub” Davis: 9 Years

Tommy Champagne: 3 Years

Rickie Fitzsimmons: 1 Year

Jason McCranie: 3 Years

Cris Simmonds: 1 Year

company news & updates

VESSEL NEWS:

M/V Lake Verret

BIG CHANGES to Dupre Marine!

Our newest addition to our fleet as of mid September is the M/V LAKE VERRET! Captain Robert Conklin and crew already have that DMT blue on their new vessel. If you haven’t seen them yet, you soon will so be sure to share your photos of them!

M/V LAKE VERRET

More vessel news will be coming soon for the M/V Alva Dupre, that is currently in the shipyard getting remodeled with a new name….to be announced soon!

SHORESIDE NEWS:

Kevin Daigrepont is now proudly serving as Dupre Marine’s On-Board Trainer (OBT)! As of late July, Kevin transitioned from his esteemed position with the Vessels to a Shoreside role. However, he will still actively participate on the tankering boats, where he will take on the responsibilities of overseeing training for Tankermen, conducting all annual audits, and assisting in the development of new Tankermen as they are prepared to operate independently. With a remarkable background as a Tankerman for 11 years, Kevin has proven to be an invaluable asset to the team, and we are truly grateful to benefit from his extensive expertise in this new Shoreside capacity.

Kevin Daigrepont

Other DMT Company Info:

If you haven’t already, please join or make changes to your Dupre Marine 401 K plan with Edward Jones. If you have any questions, please call Jamie at the office during office hours. Changes can be made to this plan in writing at the beginning of each Quarter.

If you have ANY changes to your personal info, marital/child status, banking info, please let Jamie or Karly know as soon as possible! You can call during office hours or email directly jrobichaux@dupremarine.com or kboudreaux@dupremarine.com. Please also know that any of these changes must come directly from the employee.

We have a new form below for our crew members to order extra uniform items from Karly for payroll deduction.

A reminder ALL deckhands and tankermen who work on any vessel in unit tow service must be clean shaven, regardless if our crew members are tanking or shore tankermen are utilized. Any wheelmen with facial hair must be neat and trimmed as specified by Calvin or Frank for the customer requirements. This is a DMT policy as well as our customers’ policy. It is for your safety.

Stop right now and check the expiration dates on all your credentials (MMC, Medical Card, TWIC, Drivers License, etc). Although we track your info in Helm, lately it is not enough time before expiration. With your time on the boat and the time it takes to get the process done, you could expire and not be able to work. It could take a couple months to several months. Please get with Karly if you need any help with your MMC. And here is the link to renew your TWIC card online https://universalenroll.dhs.gov/programs/twic

This is your livelihood, your career, so keep track of it please!

Do you get stuff shipped to the office for crew change? We are more than happy to get your packages to the vessel, but please help us out and text/call/email to let us know when it is coming so we can look out for it.

Complete all your current and due Moxie online training. This is a compliance requirement, audit requirement and also tied into your Safety Reward Points that will be distributed near the beginning of each quarter

For those who are new or may not know, this website and our social media pages are filled with photos and videos sent in mostly by our crew members or Frank, Jeremy and other towboaters. If you have photos you want to share, please send them to Denise via text, email or dm on our Instagram or Facebook pages. If you haven’t done so, please check out all the amazing contributions on all our socials and this website. And we are on TikTok @dupremarinetowboats for any video contributions!

If any of our crew members would like to contribute content to future newsletters, please email Denise dmorencie@dupremarine.com

Office hours are 0800-1700 Monday to Friday, please note the times you contact shoreside during off hours when it is not urgent. If it can wait until office hours, please call then, and of course if it is urgent call the necessary contact for the problem.

uniform orders

This form is only for vessel employees for Dupre Marine Transportation. Uniform gear listed are for Dupre Marine crew members only. No other orders will be accepted and form will be discarded if not a current employee or outside the company.

submit NEAR MISses OR STOP WORK RESPONSIBILITY

We always track all Near Miss and Stop Work entries submitted by our crew members, but this year we are focusing on how many near misses are submitted by each boat per month and sending those numbers to the boats. We are doing great so far, so lets keep it up and surpass all other years. And submitting a Stop Work Responsibility is such an important safety tool. As Calvin noted in a recent newsletter:

“Stop Work Responsibility is important because it empowers employees at all levels immediately. It doesn’t matter what your position is, how long you have been employed at the company, or even your overall experience level in the industry. Everyone has the tool, and it is everyone’s responsibility to use it when circumstances dictate. Stop Work removes the red tape and forces everyone to take a look at the hazards.”

pump up those numbers!

〰️

pump up those numbers! 〰️

Remember to submit your Near Misses and Stop Work Responsibilities in Helm regularly. They are not only strong safety learning tools, but also recognized in the charter group and rewarded from Kirby Inland Marine. An important recognition!

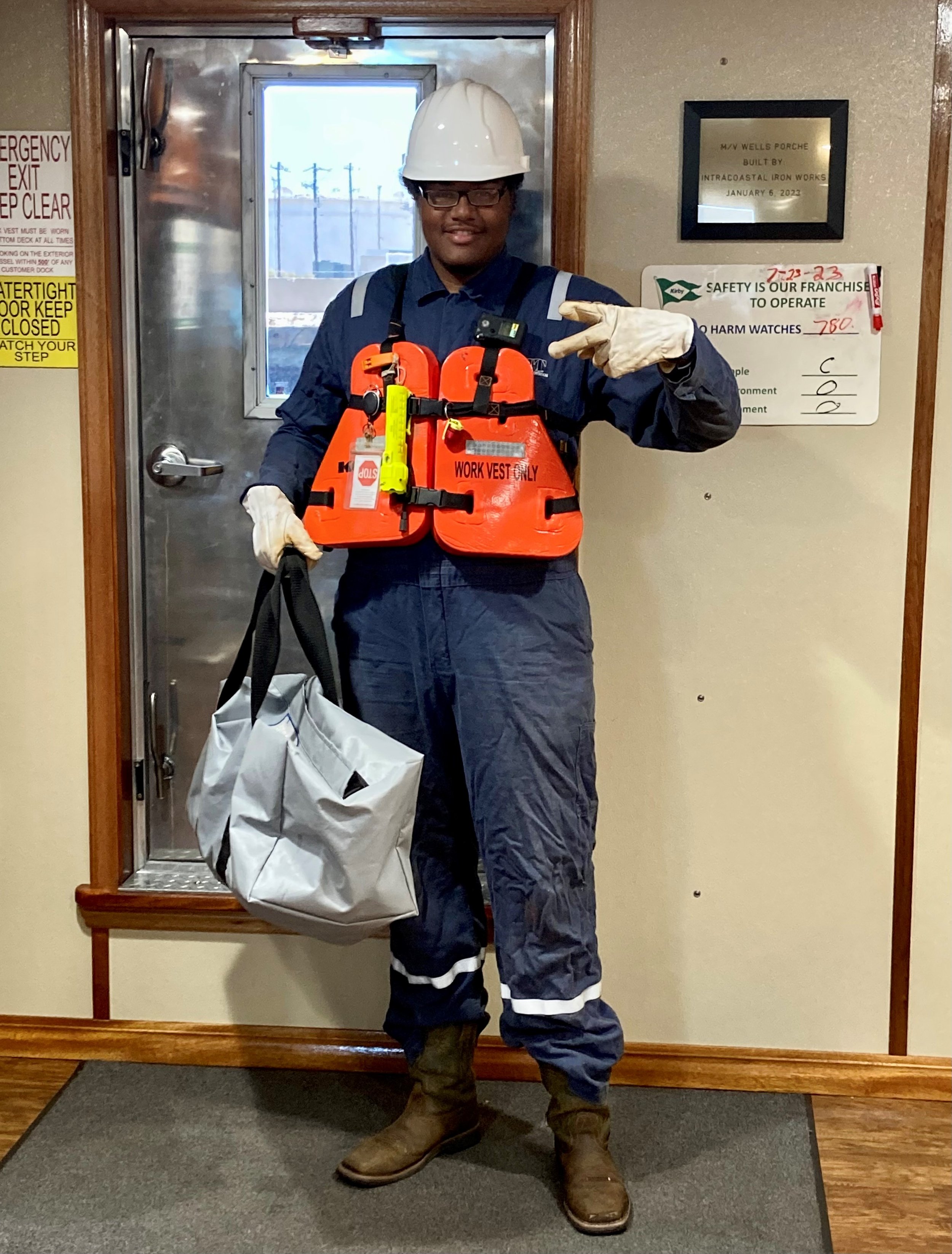

know the correct PPE for any job

⚠️ If you have any questions concerning your PPE, please contact Port Captain Frank Bumgarden

⚠️ Always be ready to work wearing the proper PPE and wearing it correctly! Your PPE will NOT protect you if it is not the correct type, is damaged or worn and if is not on correctly and adjusted properly!

⚠️ Be responsible and know what PPE is required to use in your particular work situation Check yourself and ask yourself if you have on what is needed and required to be safe for that job

⚠️ Steel toe boots are required footwear. All Dupre Marine crew members will get $100 towards new boots: all deck crew every 6 months and wheelhouse every year. Please get with Lynsie or Michael when you need to purchase new steel toe boots. We use Joe’s Boots in Houma, which we will payroll deduct the amount over $100 or you may purchase elsewhere and submit your receipt to Lynsie or Michael for a reimbursement up to $100. We are now tracking boot purchases. Deck crew this is an important part of your PPE, so please make sure your boots are in good shape always. Captains, please inspect the boots of your crew regularly. If you have any questions, please contact Frank.